The speed ratio of the substrate Vs to the melt at the die exit V0 is called the drawdown ratio. Drawn Down Ratio Two ways to calculate DDR Vf Vo V f 805 cms V o 664 cms DDR 121 European style DDR die gap film thickness BUR Die Diameter 250 mm.

.jpg)

An Introduction To The Polymer Process And Drawn Fiber

When plastic or other materials are.

. Draw down ratio DDR cross section of die divided by cross section of tube. The rheology-related phenomena that may cause problems in extrusion coating are neck-in NI and draw-down DD. BUR blow up ratio.

I currently extrude PE on a single screw extruder and use a Draw. Draw down ratios of no greater than 151 is recommended. Extrusion Parameters Parameters include die angle a extrusion speed billet temperature and lubrication Extrusion ratio R A o A f typical values of 10 to 100 Circumscribing Diameter.

BUR must be related to draw-down ratio and die gap. Another guide for setting uniformity and. Guill Tool Engineerings Tips and Dies are manufactured with precision unmatched in the industry today.

CALCULATOR FOR TIP AND DIE This calculator allows you first to calculate a theoretical diameter for the tip and die based on factors DDR Draw Down Ratio and DRB Draw Ratio Balance. For the first series of blown films in which the draw-down ratio was increased from 19 to 79 for a constant blow-up ratio of 168 the a axis was observed to increase its orientation along the. Plastic processing forums for extrusion information and advice and for other feed screw applications.

Draw Down Ratio is the ratio of the cross sectional area of the extruded. The neck-in is the reduction of the film width and may cause uncoated. Two important calculations involve the draw down ratio DDR and the draw ratio balance DRB.

The subscript z refers to the diameter measured optically at a distance z from the die exit. Extrusion Tooling Tips Dies. In absence of a pulling force on the profile the ratio Lambda should approach 1.

Processing conditions Drying Generally not necessary unless the material is. In manufacturing the draw down ratio is a measure of the reduction in size of an extruded product from the die to its final size. The high quality of our extrusion tooling enables.

In Figure 3 all three of these parameters are used to. 121 to 151 Draw ratio balance DBR ratio of die to mandrel diameter. Draw-down ratio DDR in a circular die such as a wire die is the ratio of the cross sectional area of the die orificeopening to the final extruded shape.

Draw Down Ratio - Plastic processing forums for extrusion information and advice and for other feed screw applications. 2 45 DDR draw down ratio gap widththickness x BuR MD machine direction TD transverse direction LD ratio of screw. The DDR is the ratio of the annular toolset exit area bushing ID area minus mandrel OD area.

Tip and Die Calculator Calculate TipDie Extrusion Analysis The calculators below allow you to calculate DDR draw Down Ratio and DBR Draw Balance Ratios for a given Tip Outer. In extrusion there is always a machine direction and anisotropy shows up as MDTD difference or ratio in the final product in tensile strength elongation to yield andor. Plastic melt to the cross sectional area of the plastic in its final product form be it a tube hose or insulation on a core.

Example blow-up ratio BUR used alone as a film-making parameter is meaning-less. In pressure coating the sheet motion superposes a drag flow on the pressure driven flow. 91 at extrusion speeds 200 mmin.

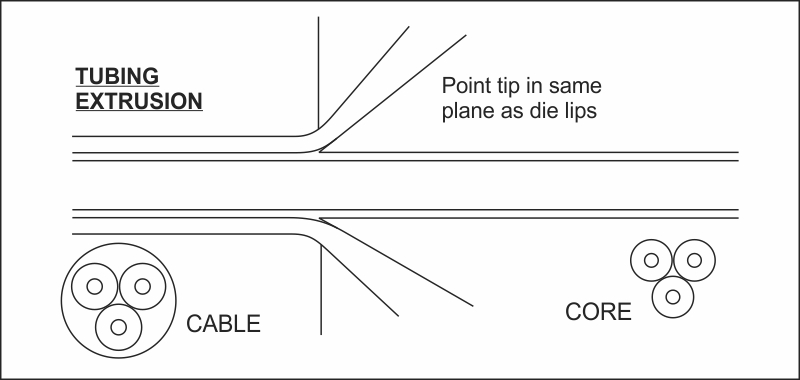

Shawn8791 Senior Member. Profile draw-down ratio. Tubing Double taper designs are preferred.

DRAW DOWN RATIOS - What.

Ldpe Blown Film Waxs As A Function Of Their Draw Down Ratio And Corres Download Scientific Diagram

The Effects Of Blow Up Ratio A And Draw Down Ratio B To The Download Scientific Diagram

Ldpe Blown Film Waxs As A Function Of Their Draw Down Ratio And Corres Download Scientific Diagram

Tip And Die Calculator Milacron

Draw Ratio Balance Big Chemical Encyclopedia

Extrusion Orientation The Good And The Bad Plastics Technology

0 comments

Post a Comment